Mica Capacitors

Mica Capacitors are crafted using the finest quality Indian ruby muscovite mica, meticulously chosen to ensure optimal electrical characteristics. These capacitors exhibit exceptional stability even under high temperatures, making them highly reliable.

To construct these capacitors, mica films are screen printed with a special silver paste and interleaved with metal foils for contact, resulting in stacked layers. The terminals, composed of copper-clad steel wire with a copper coating offering at least 30% conductivity, are carefully attached to the stacks. A tin coat finish is applied to enhance solderability.

To provide enhanced protection, the clamped unit undergoes a vacuum dipping process with epoxy and is conformally coated with epoxy powder. This enveloping technique imparts high resistance to moisture and heat, ensuring the longevity of the unit.

The careful selection of raw materials, combined with continuous monitoring of equipment and fabrication processes, guarantees a consistently high level of quality that aligns with the stringent requirements of sophisticated electronic equipment.

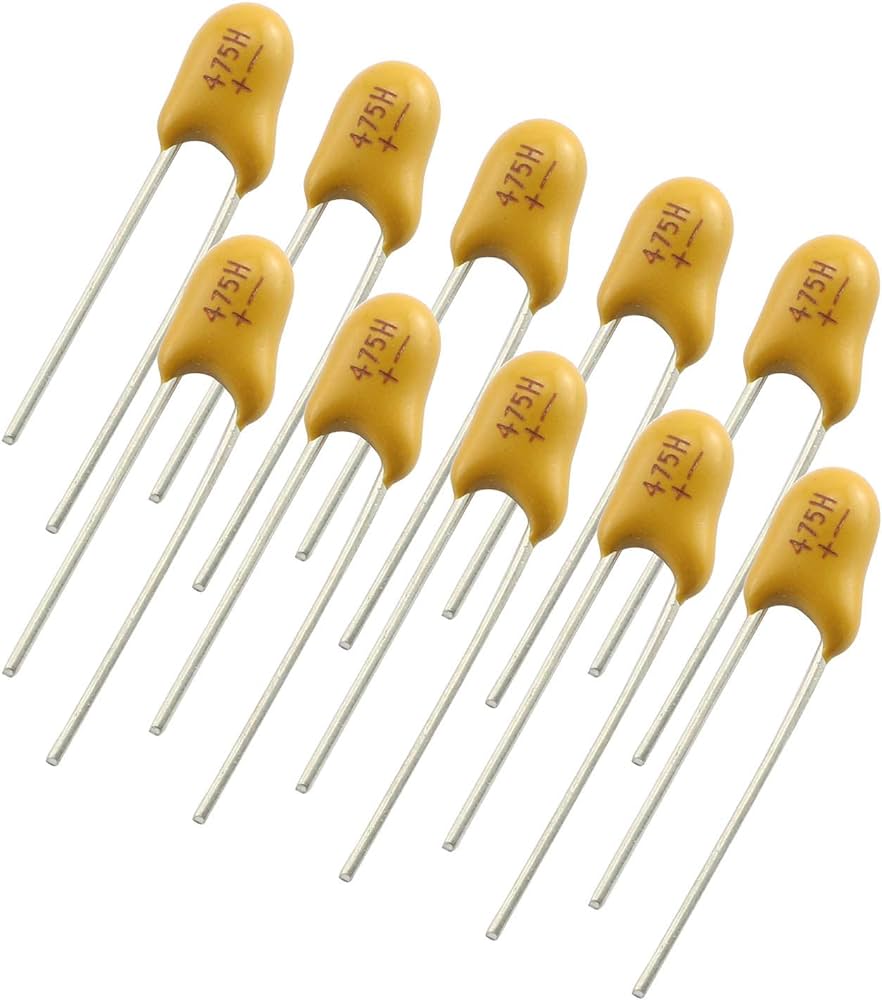

Tantalum capacitors

Tantalum capacitors, renowned for their stability and reliability, are meticulously crafted through a rigorous manufacturing process. The journey begins with the grounding of metallic tantalum into a fine powder. This tantalum powder is then meticulously pressed into cylindrical forms before undergoing a high-temperature sintering process.

This crucial step, conducted under vacuum conditions at temperatures ranging between 1,500 and 2,000 °C (2,730 and 3,630 °F), transforms the powder particles into solid pellets, ensuring structural integrity and optimal performance. These pellets are coated with tantalum pentoxide, providing essential dielectric properties.

Following coating, tantalum pellets are assembled with conductive layers, typically made of tantalum powder or wire. The assembled capacitors are encapsulated in epoxy resin casings to shield them from environmental factors and ensure longevity.

Through precise craftsmanship and stringent quality control, tantalum capacitors offer unmatched performance and durability in demanding electronic applications.

Potentiometers

Potentiometers, crucial in electronic circuits, are crafted with precision and reliability in mind. High-quality resistive materials like carbon or conductive plastic are machined into a uniform resistive element. This element is assembled with a wiper mechanism made of conductive materials like silver or gold-plated brass, ensuring smooth and accurate variable resistance.

The assembly is housed in a sturdy enclosure, often made of high-grade plastics or metal alloys, providing both protection and stability. Terminal connections of high-conductivity metals facilitate electrical connections. Rigorous testing and calibration verify performance, including resistance range and linearity, ensuring adherence to specifications.

Throughout manufacturing, strict quality control maintains consistency, resulting in potentiometers that meet the demanding needs of modern electronic systems, offering precise and reliable control in various applications.

We also offer

Copper Leads

Metallurgical Bonding

Thin Coat (Single Dip) For High Installation Density

Crimped And Cut Leads